|

High Voltage

Transformer Installation

The first challenge when

looking for replacement parts was finding the right high voltage

transformer that not only is the right size to fit the chassis, but having the right voltage and

current capabilities.

I searched several sources for a compatible high voltage

transformer and settled on the transformer from a Heathkit

SB-220 Amplifier. The transformer seemed to be a

good fit, it does produce a little more

high voltage, and it is

a bit smaller than the transformer in the original L4PS power

supply. It has the

dual 110VAC primary windings to operate at 110 or 220VAC and has

tapped secondary high voltage windings for the "Tune" and "Operate"

Modes. high voltage, and it is

a bit smaller than the transformer in the original L4PS power

supply. It has the

dual 110VAC primary windings to operate at 110 or 220VAC and has

tapped secondary high voltage windings for the "Tune" and "Operate"

Modes.

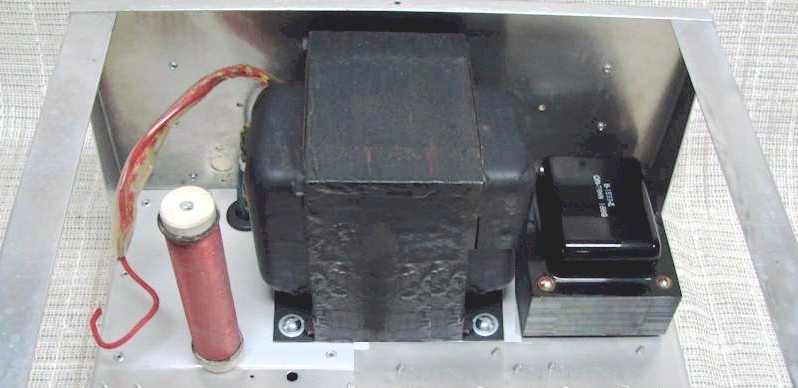

As shown

in the picture below I mounted the transformer along the back of

the chassis as close to the filament transformer as practical.

I did this so I had maximum space to mount the power supply

board on the opposite side and to allow for good air flow for

cooling. The aluminum plate I installed earlier

provided a solid mounting surface for the transformer.

I ran the primary winding under the chassis in the back corner

and the high voltage secondary winding were left above the

chassis to connect with the power supply circuit board.

I also mounted the plate choke to the left of the transformer to

give me the proper distance to reach the tube and prevent arcing

to the transformer.

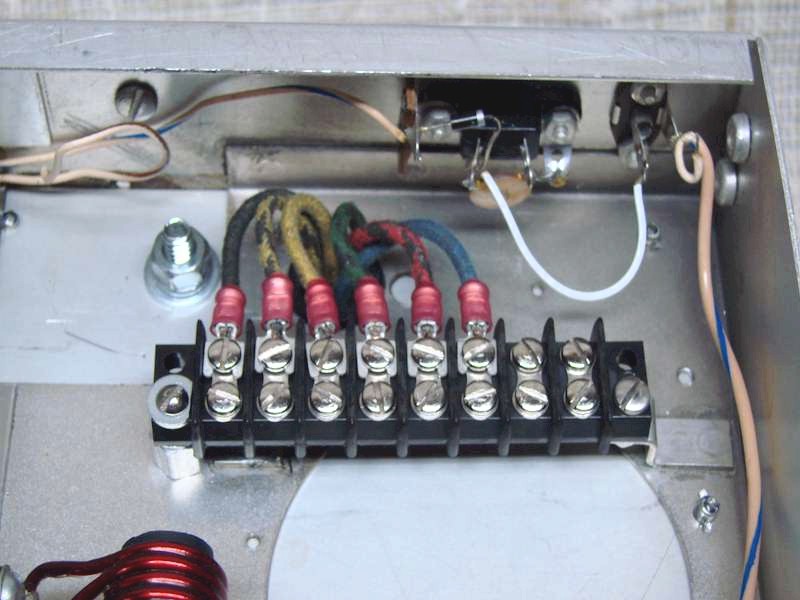

Under the

chassis, shown below, I brought the both primary windings to a terminal strip

so it could easily be wired to operate at 110 or 220 volts.

Each primary winding is a tapped winding which is used to switch

between the the "Tune" and "Operate" modes.

Since that switching is the same for either the 110 or 220 volt

operating voltage I used a small

relay to do that switching. This way I eliminate the vulnerability of the power switch

contacts from arcing internally and welding together due to the

high current being switched. This is a very common

problem in that power switch which prevents it from switching

between the "Tune" and "Operate" mode.

The photo on the left shows the transformer

primary wiring to the terminal strip. From left to right

the two primary winding are in groups of three wires

In each group the black dual color stripped wire is the

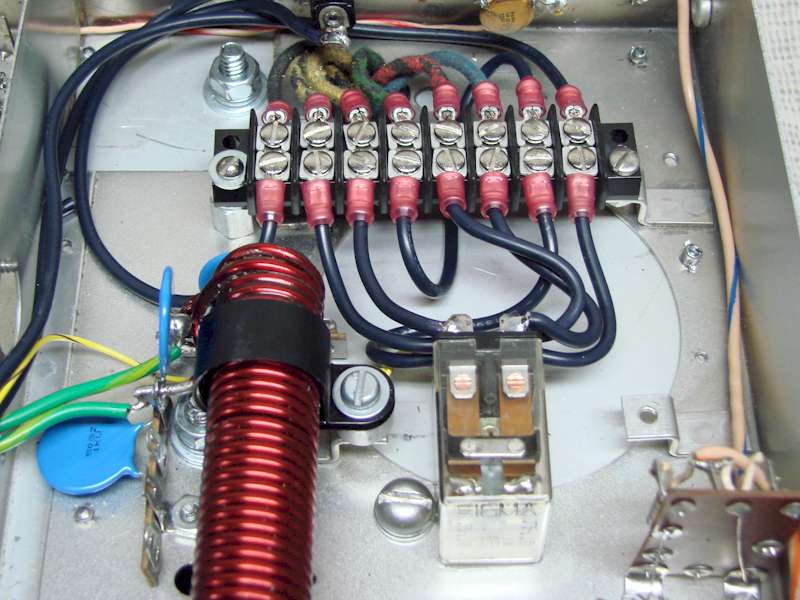

tapped connection to the winding. In the picture on the

right shows the wiring for 220 VAC operation. The relay

switches the winding tap connections for the "Tune" or "Operate"

mode. The difference being lower high voltage

for amplifier tune-up purposes. Power output

between "Tune" to "Operate" is approximately 150 watts of

additional power. The relay now operates from the front

panel "Tune / SSB" switch to the low voltage power supply.

This eliminates the common problem of the front panel power

switch arcing and welding the switch contacts together.

The large 8 pin connector on

back of the L4B chassis, originally connected to the L4PS power

supply is now the primary power connector for the new design.

The connector, depending on how the amplifier is jumpered

internally, will except either a 110VAC / 220VAC input. The circuit

breaker protection for the amplifier was originally in the L4PS

power supply. In my design there is very little rear

chassis space to accommodate circuit breakers so I decided to

use fuse holders. Since there are now two

transformers each receiving primary power, I decided to install

a separate fuse holder for each one. Shown in the picture

to the left next to the 8 pin power connector is the chassis

mounted fuse holder for the filament transformer.

The high voltage transformer fuse holder is the same type fuse

holder but

mounted on the other end of the chassis near the high voltage

transformer. Both fuse holders use a 15 AMP fuse for

110VAC or 10 AMP fuse for 220VAC.

|

![]()

![]()