|

By: Mark Gilger / WB0IQK

|

-

-

-

-

-

-

-

-

-

- Compressed air

spray can. Used for PC cleaning.

|

Surface

Preparation:

- Clean grime from

surface area with Windex, or soap & water.

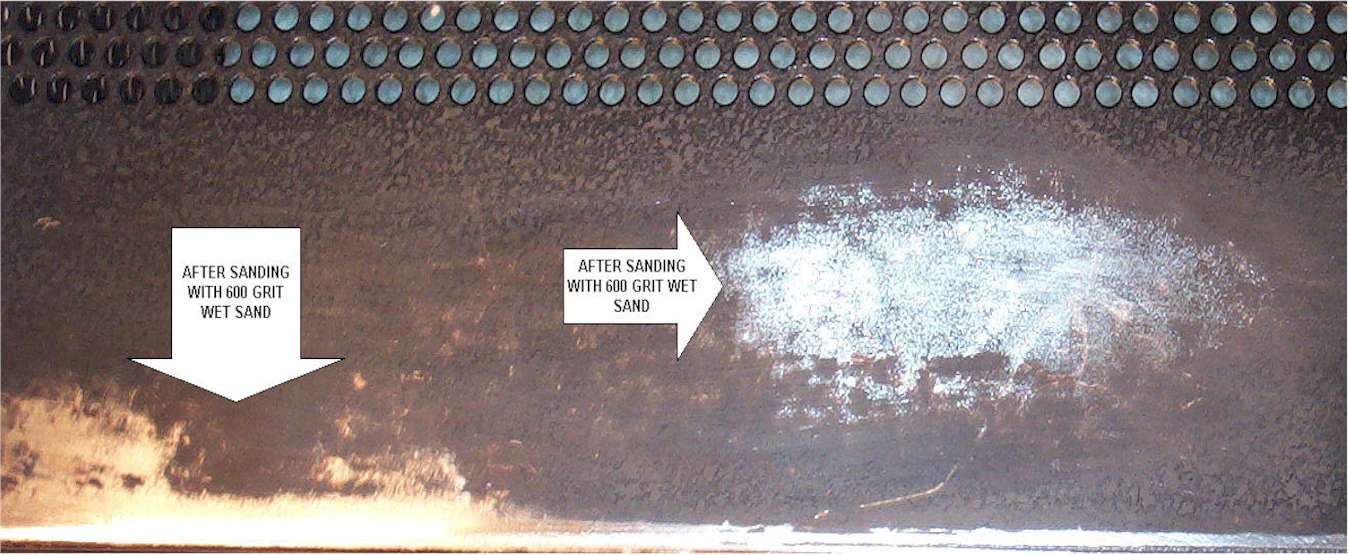

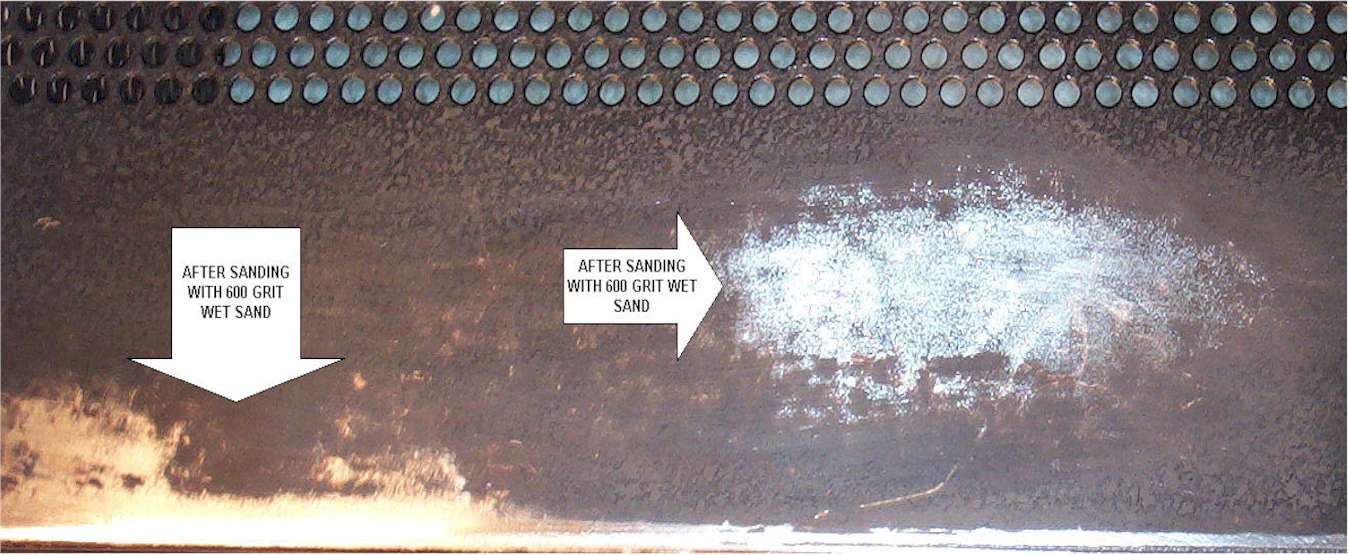

- Put #600 grit

sandpaper on the 3M sanding block and with a small amount of running

water, start lightly sanding the entire surface. Be careful not to sand

over any of the silk screen wording on the lower cabinet section.

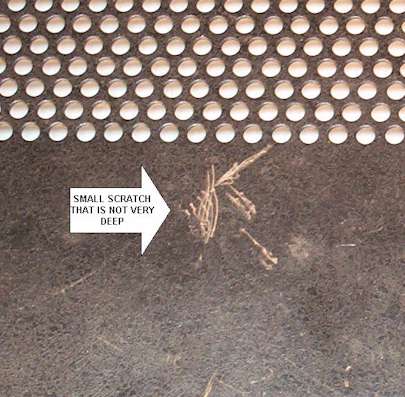

- Typical of an

old cabinet are minor, or sometime major scratches and paint chips. No

mater how small, you can not under prepare these area’s. If you fail to

prepare correctly, you will have an otherwise nice paint job, but you

will still be able to see the scratch

- After the minor

light sanding of the entire cabinet, now concentrate on the area’s with

defects. You need to meet two goals. (1) you need to feather the

area. Feathering the area simply means that you sand the defect area to

around 4 – 5 times it’s original size making sure there is a gradual

transition from painted area to bare metal. (2) When feeling the area

with you finger, you should not be able to feel defects or the

transition from painted area, to bare metal.

- Once the cabinet

has been sanded, spray the entire area with Windex or Denatured Alcohol.

Do not substitute. Try and not touch the prepared surface with

your bare hands. You don’t want any hand oils present on the prepared

surface. If you do touch it, clean area with Windex and let dry.

|

|

|

Cabinet Silk Screen Letter Protection:

-

Cabinet silk screen lettering needs to be protected during sanding and

painting.

-

During the sanding process, no preparation needs to be made other than

making sure you do not sand over the silk screened area’s.

-

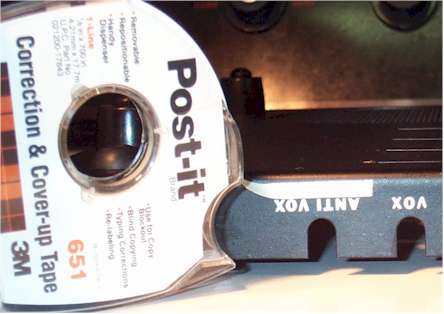

Before priming and painting, the effected silk screen lettering needs to

be covered. I’ve found that the “Post-it” brand #651 Correction &

Cover-up Tape works good. It can be obtained from just about any office

supply office. It’s used to correct typing errors when using a

typewriter. The tape is good for our purposes because it has a very

light adhesive backing and pulls away easily from the silk screened

area.

-

Trim

the tape length and height to match the word being covered.

|

Priming:

- With the Krylon

#51317 Rubby Brown Primer, prime the prepared surface with 3 or more

light coats. Let the surface completely dry before applying the next

coat. If you prefer, you can also prime the entire cabinet, but

excellent results will be obtained by just doing the effected area’s.

- Once the primer

is completely dry, wet sand the entire cabinet with #1000 grit

sandpaper.

- Once again,

verify the surface is smooth and defects can no longer be detected by

rubbing your bare fingers across the surface. If no defect can be felt,

proceed to the next step, if defects are still detectable, redo

preparation steps before proceeding.

- Spray the front

lip area with compressed air to blow out trapped water from the inside

overhang lip.

- Let cabinet dry

for several hours in the direct sunlight.

Painting:

- With Windex,

spray the cabinet to make sure the area is clean and let dry.

- With a smooth

back and forth motions, spray the cabinet with Krylon #51613 Satin Black paint. For best results, do not get any closer than 12 inches from

the cabinet. Spray 3 or more coats, letting it completely dry between

coats until the desired results are obtain.

- Sand the entire

cabinet again very lightly with #1500 wet dry sand paper using the 3M

sanding block and plenty of water until no rough area’s are detectable.

|

Painting Spackling:

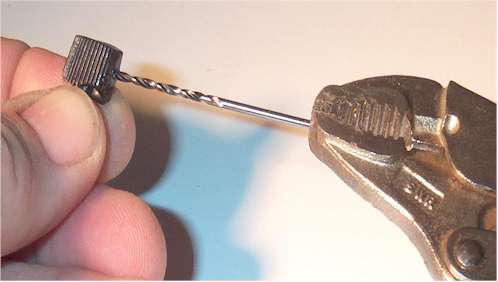

- With the proper

drill bit, ream out the spray button hole. The idea is to enlarge the

spray hole to a point where the paint sprays out more in drops, instead

of a fine mist. You might need to

experiment with drill bit sizes until the desired results are obtained.

I’ve found the #51 bit works best for the Drake cabinets.

experiment with drill bit sizes until the desired results are obtained.

I’ve found the #51 bit works best for the Drake cabinets.

- With the can

positioned about 2 feet from the cabinet, using smooth back and forth

motions, spray a light coat across the entire cabinet surface until the

desired spackling effect is obtained.

- Remove the tape

covering the silk screening.

- In most cases,

you can make an ultra light sanding with the #1500 sandpaper over the

silk screened area to remove any paint ridges created by the tape.

|

![]()