Drake Home Page Drake Technical Tips Menu

![]()

|

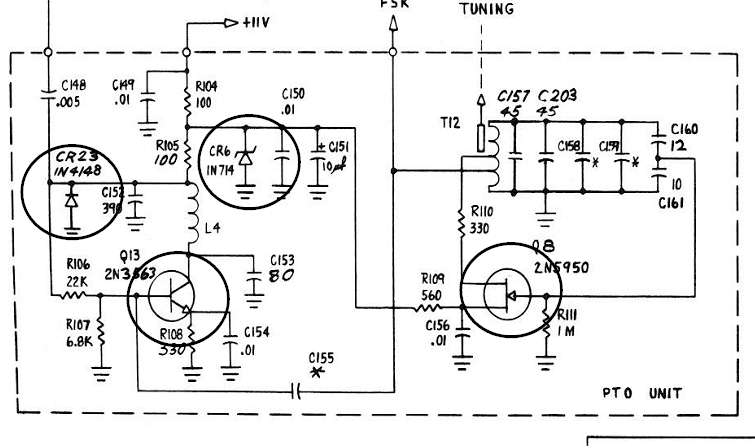

DRAKE PTO TROUBLESHOOTING Written by: Mark Gilger, WB0IQK The following procedures applies to most of the tube PTO’s except the TR3 and early TR4’s. Mechanical: There are several things that can be done to improve the mechanical operation of the PTO.

|

|

|

|

Electrical Stability:

|

|

Electrical Failures:

|

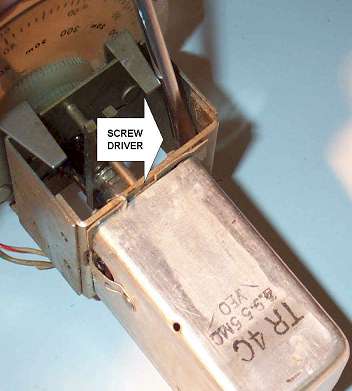

PTO COVER REMOVAL: In just about all cases, the cover to the PTO will need to removed and the PTO assembly removed from the unit.

|

|